Key Terms in On-Site Machining: A Comprehensive Guide

On-site machining, also known as in-situ machining, refers to performing precision machining operations directly at the worksite, eliminating the need to transport heavy equipment to a workshop. This cost-effective and time-saving process is vital across industries like oil and gas, power generation, mining, marine services, and more. Whether you're a professional or someone eager to learn about the field, understanding key terms used in on-site machining is essential.

Here, we explore essential terms that form the foundation of on-site machining.

Portable Machining Tools

Portable machining tools are specialized, mobile machines designed for on-site machining tasks. These tools are lightweight, easy to transport, and provide versatile machining capabilities at the worksite. Common examples include portable milling machines, portable lathes, flange facers, line boring machines, and portable drilling machines. These tools help professionals perform precise repairs and modifications directly on-site.

Line Boring

Line boring is a precision machining process used to restore or align the internal diameter of a cylindrical hole. This is crucial for repairing large machinery components like engine blocks, turbines, or gearboxes. Portable line boring machines are essential for cutting new bearing surfaces or realigning worn ones, ensuring machinery operates at peak efficiency.

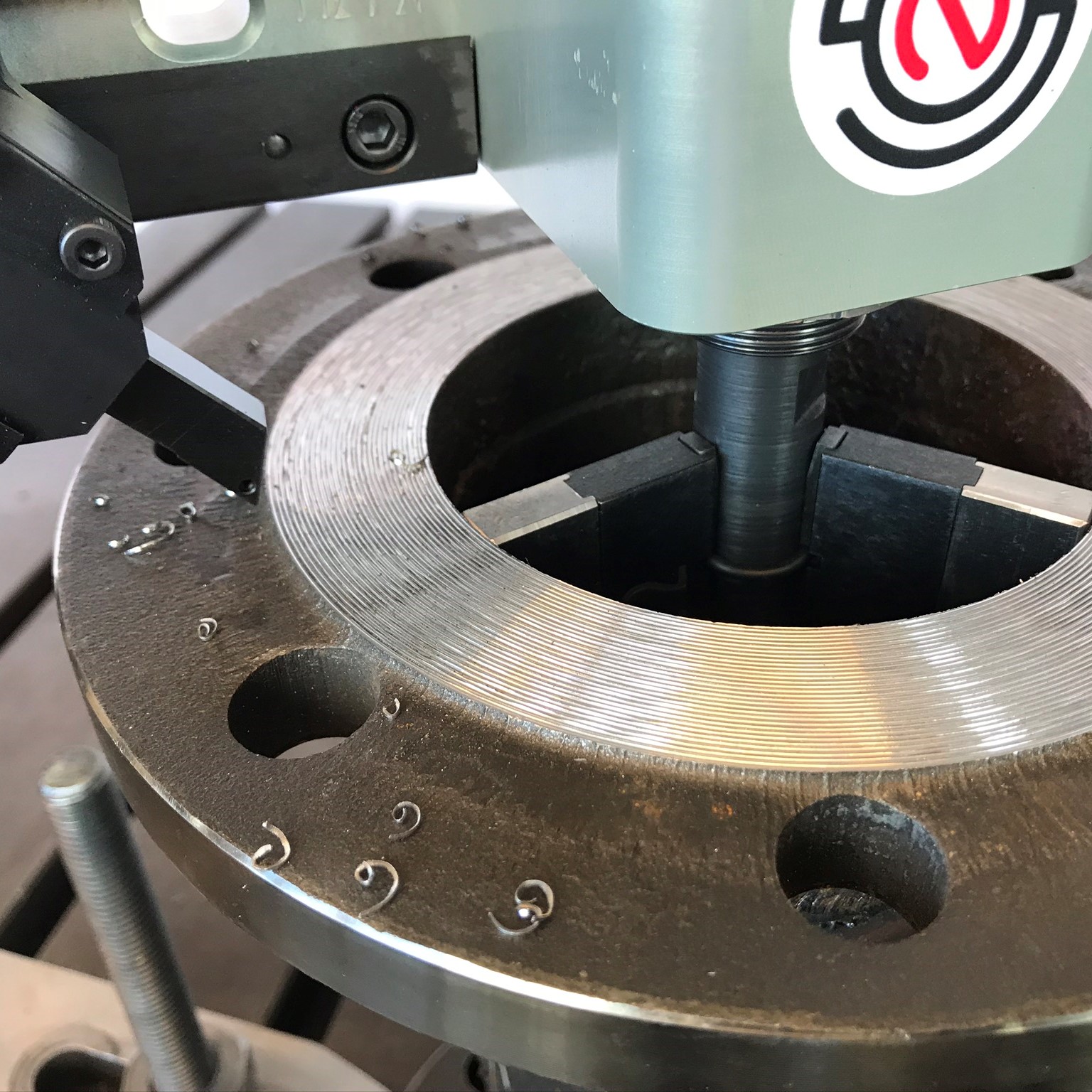

Flange Facing

Flange facing involves machining the mating surfaces of a flange to ensure a tight, leak-proof seal between connected parts. Portable flange facers are used to create smooth, accurate surfaces on flanges, which is critical for maintaining system integrity in piping, valve, and machinery installations.

Milling

Milling is a common machining process that removes material from a workpiece using rotating cutting tools. In on-site machining, portable milling machines are used to mill keyways, slots, and complex surfaces on large components such as turbine casings, pump bases, or structural parts. On-site milling eliminates the need to disassemble and transport large parts for repair.

Turning

Turning involves rotating a workpiece while a cutting tool removes material, creating cylindrical components. Portable lathes are used in on-site turning operations to machine large shafts, rollers, and other round components. On-site turning reduces downtime and allows for in-place repairs.

Drilling

Drilling is the process of creating holes using a rotating drill bit. Portable drilling machines offer flexibility and precision in on-site machining, allowing professionals to drill accurate holes in a variety of materials, including metals, concrete, and composites. This is particularly important in repair operations where accuracy is crucial.

Cold Cutting

Cold cutting is a method of cutting metal without generating heat or sparks, often used in environments where ignitable gases or liquids are present. This method utilizes pneumatic motors and low cutting speeds to avoid sparks and thermal damage. Cold cutting also prevents the creation of heat-affected zones (HAZ), ensuring the integrity of the material is preserved.

Machining Tolerances

Machining tolerances refer to the allowable variation in a part's dimensions during machining. On-site machinists must meet strict tolerance requirements to ensure components function properly. Achieving precise tolerances in the field is critical for safety, reliability, and performance.

Surface Finishing

Surface finishing involves refining a machined surface to meet required smoothness or appearance standards. On-site grinding, polishing, or lapping tools are used to achieve the desired finish, whether it's removing imperfections or creating polished, smooth surfaces. Proper surface finishing is vital for ensuring a component’s performance, especially in high-stress environments.

As industries increasingly rely on on-site machining for maintenance and repair, understanding these key terms is crucial for both professionals and newcomers. Familiarity with terms like portable machining tools, line boring, flange facing, cold cutting, and machining tolerances will give you a solid foundation to appreciate the precision and efficiency of on-site machining operations.